Cracking Mechanism

CRACKING is poured into holes drilled in rocks or concrete the expansive stress gradually increases with time, the material to be cracked undergoes a process of Crack Initiation, Crack Propagation and the increase of crack width. Therefore this fracture mechanism is distinguished from a breakage by blasting.

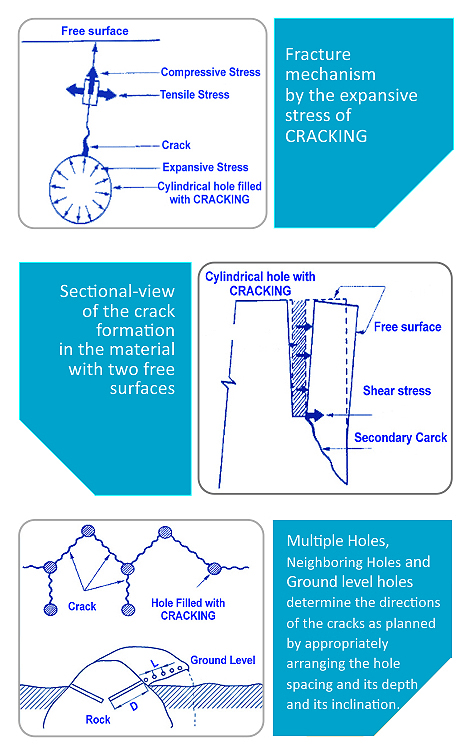

The mechanism by the expansive stress of CRACKING is shown in (Fig. 1) Cracks initiate from an inner surface of the hole, being caused by tensile stress at a right angle with the compressive stress which occurs by the expansive stress of CRACKING.

The expansive stress of CRACKING continues even after the appearance of cracks, the cracks propagate and also new cracks initiate during the process. Usually for a single hole 2-4 cracks initiate and propagate. When a free surface exists the crack as shown in Fig. 2 pushed apart mainly by the shear stress and a secondary crack also arises from the bottom of the hole running toward the free surface.

When multiple numbers of holes are filled with CRACKING that are properly adjacent to each other the cracks from the hole propagate to connect with the neighboring holes, as shown in Fig. 3. It is therefore possible to determine the directions of the cracks as planned by appropriately arranging the hole spacing and its depth and its inclination. Establishment of free surface: In the case of trenching, shafting or tunneling, if all holes are drilled vertically and filled with CRACKING the crack width can not increase but horizontal cracks initiate. Therefore in order to obtain two free surfaces inclined holes or pre-splitting must be required.

CRACKING APPLICATIONS

- Granite, Marble, Sandstone, Limestone, Quartzite quarrying.

- Rocks Pre-Splitting, Fracture, Cutting, Demolishing and removal.

- Controlled Demolition or Cutting Concrete.

- Fracture and Demolition of the Concrete building and Structures.

- Excavation of Trenches and Foundations.

- Underground excavation and removing boulders.

- Marine Excavation including underwater operations.