Cracking Instructions

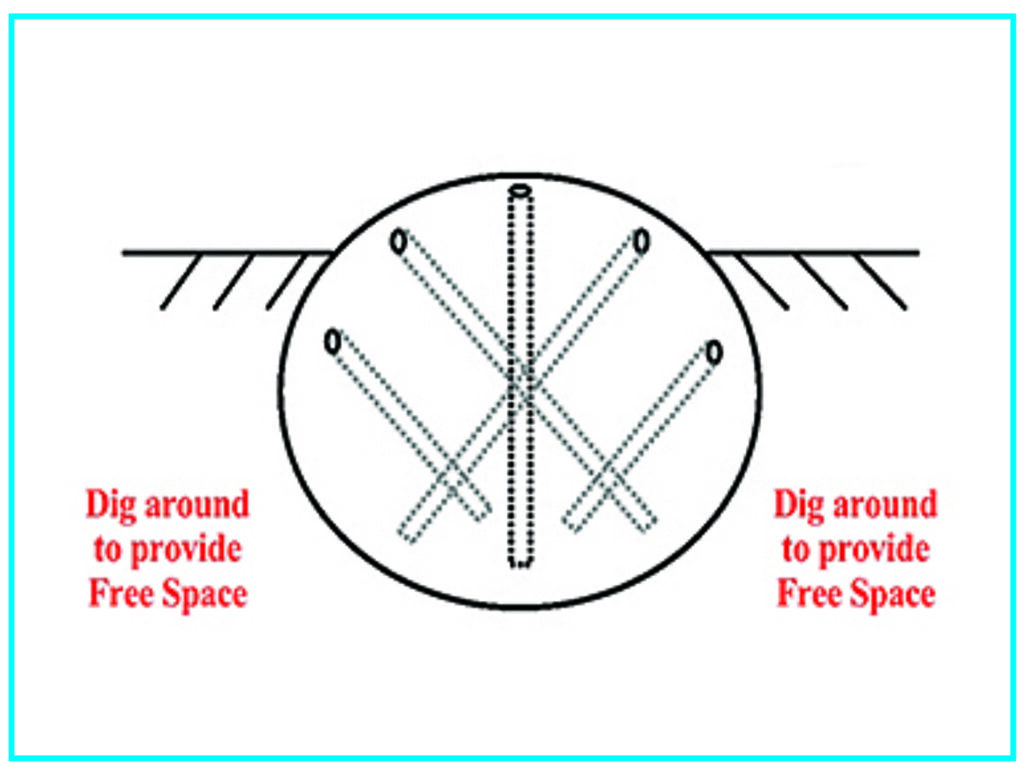

DRILLING

- Drill holes using an air hammer drill and appropriate drill bit specific to the rock type.

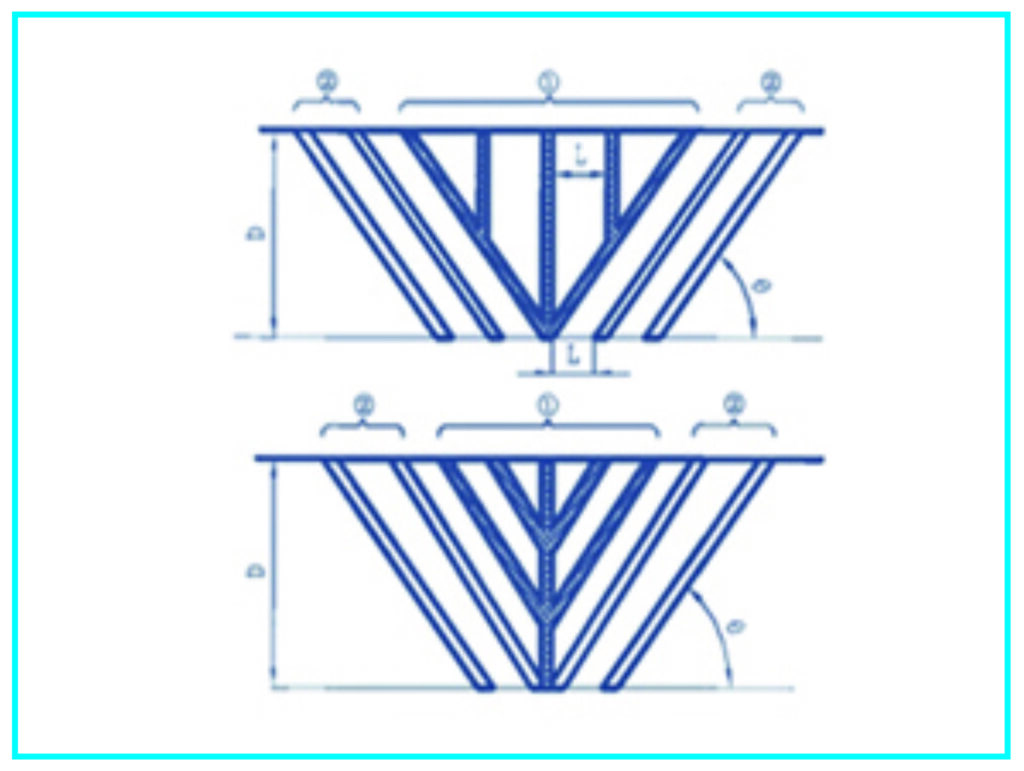

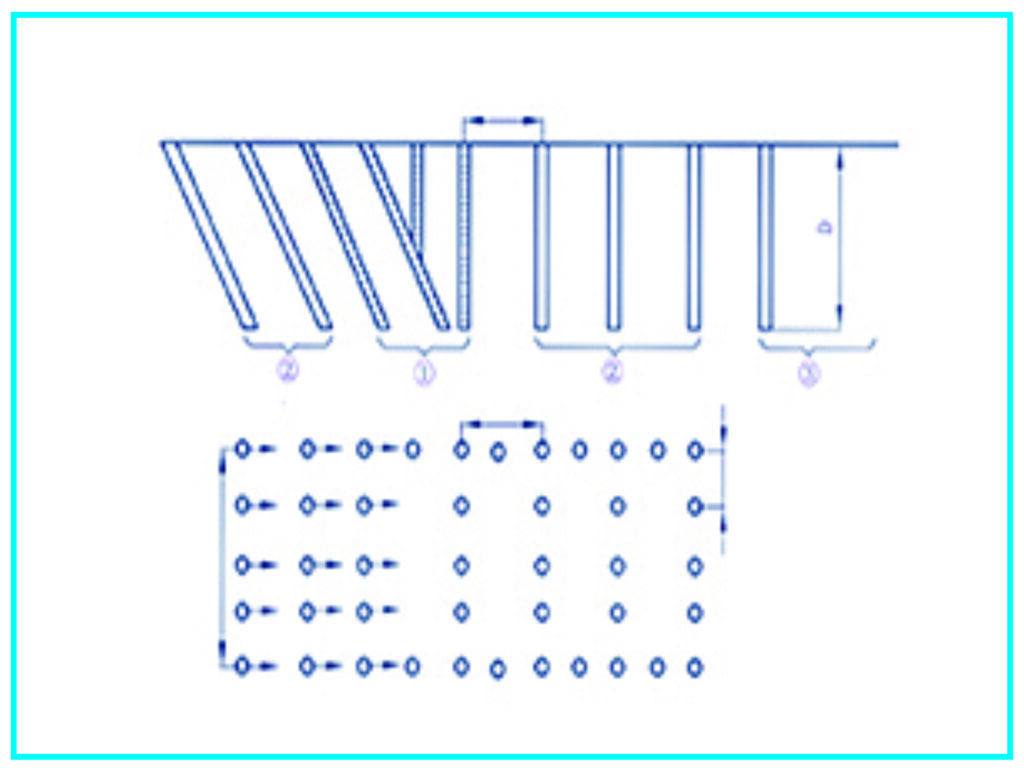

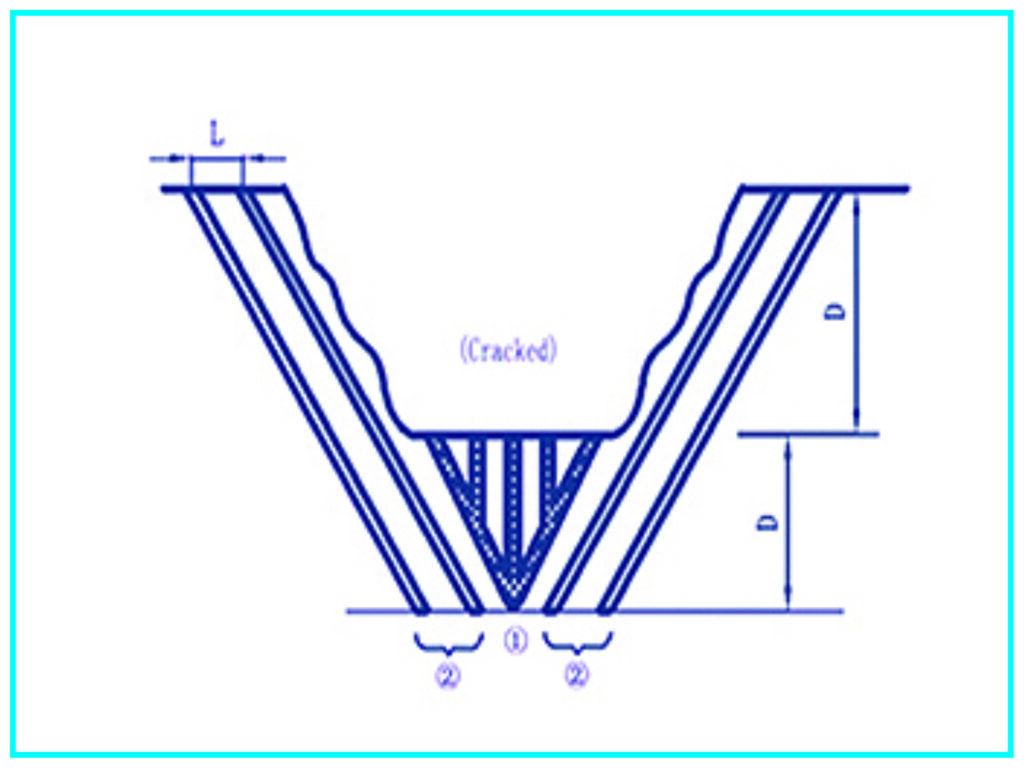

- Holes should be drilled no further than 30-60cm (1ft-2ft) apart.

- Note: In reinforced concrete recommended no more than 20cm (8″ Inch) apart.

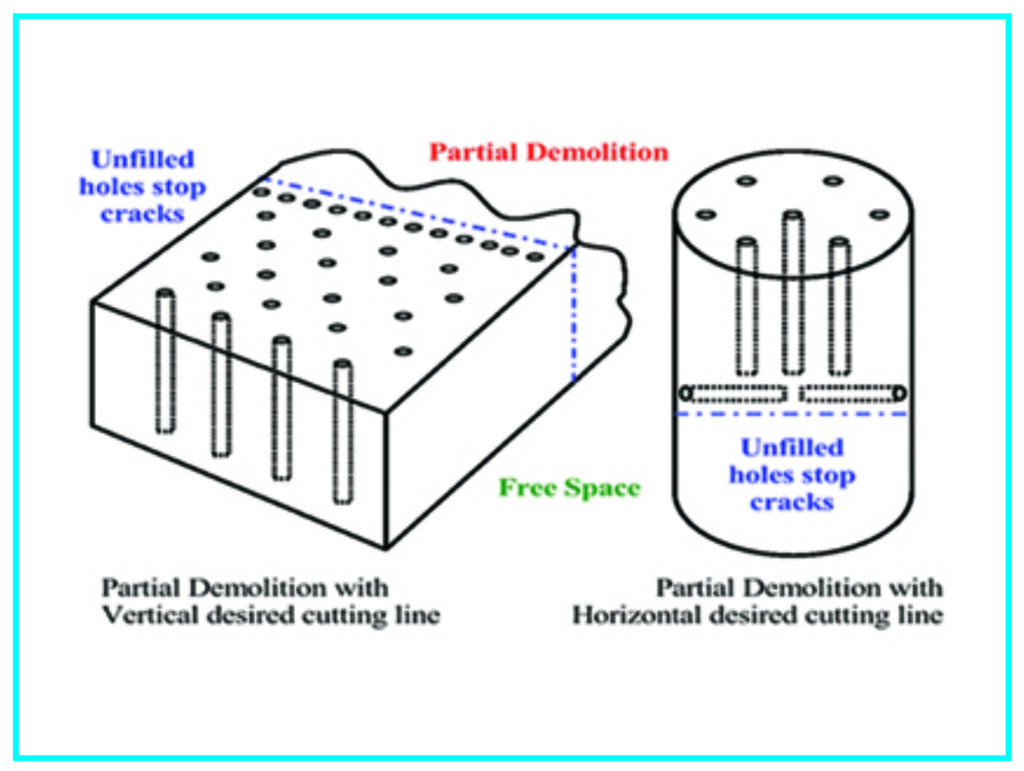

- Recommended hole diameter 32mm – 50mm (1 ½” – 2.0″). Depth would be 70-90% of the way through depending on the type of rock/material to be removed.

Crack / Cutting Time :

The cracks appear in 30 minutes – 2 Hrs after filling, depending on the weather, rocks, and hardness of target. The cracks become wider within time (maximum 24 hours expanding time)

Mixing

For regular safety reasons and mixing small amounts by hand, it is recommended to use rubber gloves. In a bucket combine 1.5 Litres of water to 5kgs bag of CRACKING, or Combine CRACKING at a ratio of 1:3 units by weight. Mix well, using a drill and paddle is recommended. If mixing with a stick or other method, make sure powder is completely dissolved into the water. Mix to a slurry.

Filling

- Clean Holes before filling using air hose remove excess dust from drilling.

- CRACKING slurry should be poured into holes within 15 min after mixing, only fill the holes to about top.

- Mix well and pour into holes while agitating the hole to make sure no air gaps & bubbles in the hole.

- For Horizontal holes, a grouting pump would be most reliable to operate or you can insert a slightly smaller plastic pipe into the hole, and then fill the expansive mortar into the pipe slowly, withdrawing the pipe from the hole simultaneously. Quickly block the hole with a cap after filling.

Storage

- Container and storage CRACKING packed in 4 anti-moisture bags of 5 kg (11 lb.) each and placed in a water proofed carton with a total weight of approximately 20 kg (44 lb.).

- Although CRACKING is packed in anti-moisture paper bags, long storage may cause deterioration of its working ingredients. Therefore, store in a dry place and use it as soon as possible.

- When storing do not place the bags of CRACKING directly on floor, put them on a pallet and keep in a dry warehouse etc. CRACKING is stored in this manner can be effectively used for about 1 year.

- CRACKING should be unpacked before use.

- When storing the portion of CRACKING remaining after using push the air out of the bag then seal with gum tape and use as soon as possible. However, it may get exposed to moisture then there is a risk of CRACKING losing its effectiveness once the bag has been opened.

- If you receive broken bags of CRACKING then they may not work, due to the chance of moisture absorption.

HOLE DESIGN TABLE

| Material to be Cracked | Hole Design Diameter (MM) | Hole Design Length (MM) | Agrate Consumption Depth | Agrate Consumption Kg/m2 |

|---|---|---|---|---|

| Soft Stone | 35-50 | 40-60 | H + 5%H | 8-10 |

| Hard Stone | 35-65 | 40-60 | H + 5%H | 10-15 |

| Rock Cutting | 30-40 | 20-40 | H | 5-15 |

| Plain Concrete | 35-50 | 40-60 | 80% H | 8-10 |

| Reinforced Concrete | 35-50 | 15-30 | 90% H | 15-25 |

| Granite Mines / Dressing | 32-40 | Upto 25 Feet | 70 – 90% H | 5 KG / 10 – 15 RFT |

Types / Temperatures

| HSCA Types | Temperature (Celsius) | Temperature (Fahrenheit) |

|---|---|---|

| Type – 1 | 25 / 40 C | 77 / 104 F |

| Type – 2 | 10 / 25 C | 50 / 77 F |

| Type – 3 | 5 / 15 C | 41 / 59 F |

| Type – 4 | – 5 / 10 C | – 23 / 50 F |